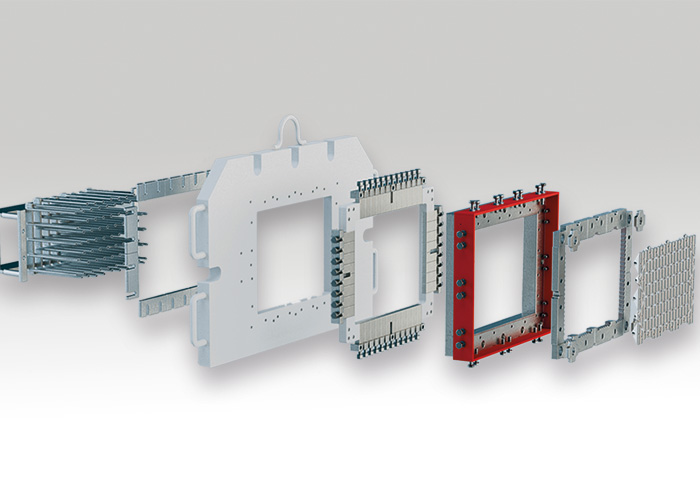

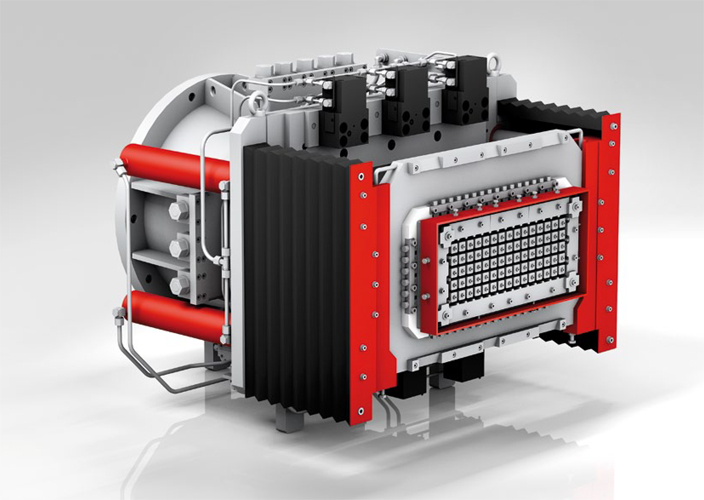

Frequent format changes and the use of very filigree dies are now commonplace in the ceramic industry. Our die cleaning unit was developed in accordance with today’s requirements.

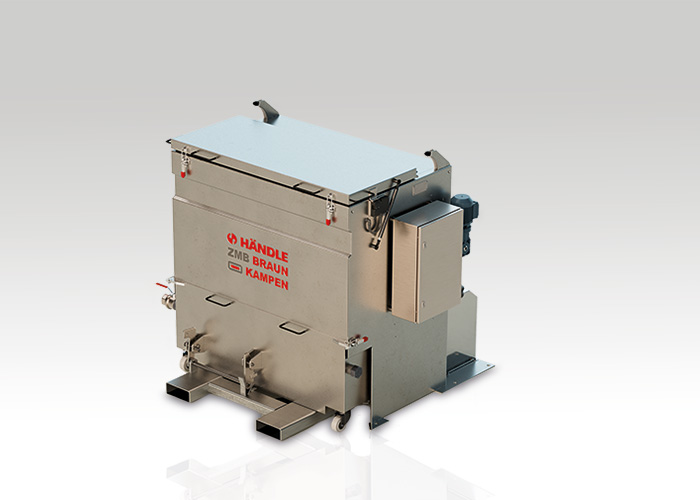

The advantages lie in the economical and environmentally friendly mode of operation. Time- and energy-saving cleaning is ensured by individually adjustable nozzles for the respective dies. Special high-pressure nozzles with optimum cleaning effect are used; this means minimized use of water and short cleaning times.

The cleaning medium is water without chemical additives. The cleaning time is between 15 and 45 minutes, depending on the die format and material.

Further advantages are the robust construction, the comfortable handling by loading from the top, the modular design with standard components and drives.

Facts | Data

FACTS | DATA

History

HISTORY

Exhibition dates

EXHIBITION DATES

Press

PRESS