Facts | Data

FACTS | DATA

History

HISTORY

Exhibition dates

EXHIBITION DATES

Press

PRESS

These are some of the milestones in the history of ZMB Braun:

Over the years, ZMB BRAUN has continuously expanded its expertise in ceramic extrusion and is now the leading manufacturer of top-quality extrusion tools for the ceramic industry and technical ceramic products.

Since Josef Braun founded the company in 1926, Braun’s extrusion dies have shaped the brick industry.

Master machinist Josef Braun founds his own company in Friedrichshafen/Kluftern.

The company’s first building goes up on Bahnhofstrasse in Friedrichshafen / Kluftern

Enlargement of the production facility and expansion of the workforce

Commissioning of the first hard-chrome plating plant

The company puts up a second building on Markdorfer Strasse in Freidrichshafen/Kluftern.

Extension of the administration building

Enlargement of the production areas and expansion of the plant’s machinery to include modern CNC machines

Construction of a new, fully automated hard-chrome plating plant

Complete overhaul and modernization of the hard-chrome plating plant

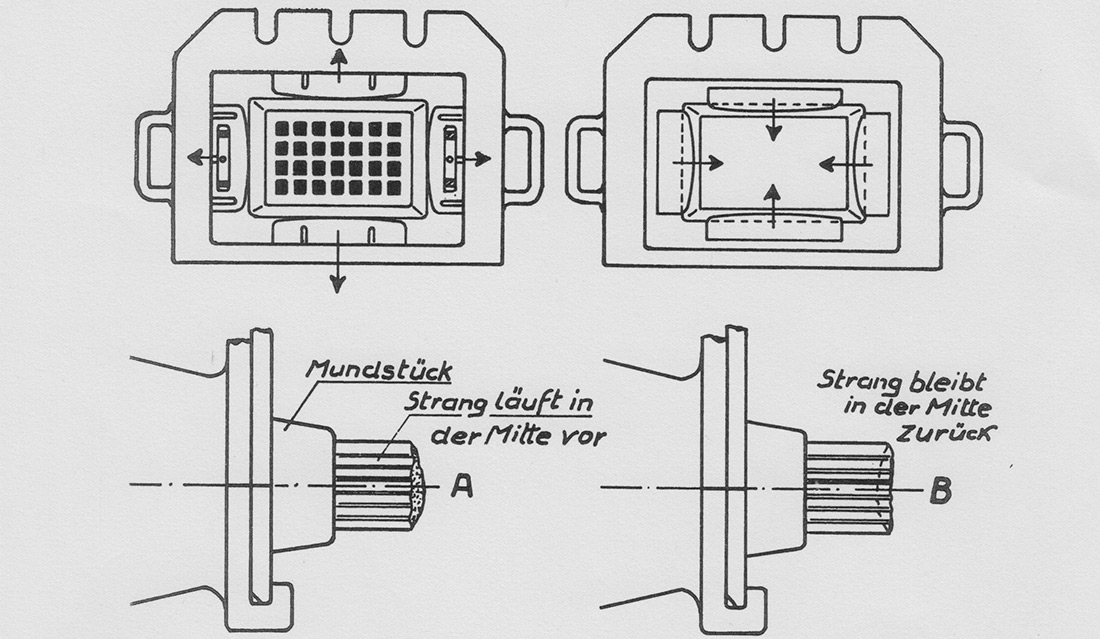

Our invention of the die inlet control feature brought the decisive breakthrough in die engineering and marked the first major milestone in the long history of ZMB BRAUN.

Invention and patenting of a machine for the production of 5-sided closed hollow blocks

Specialization in the production of dies for the brick and tile industry

Patenting of the die-inlet control feature

Construction of the world’s first large-block extrusion die.

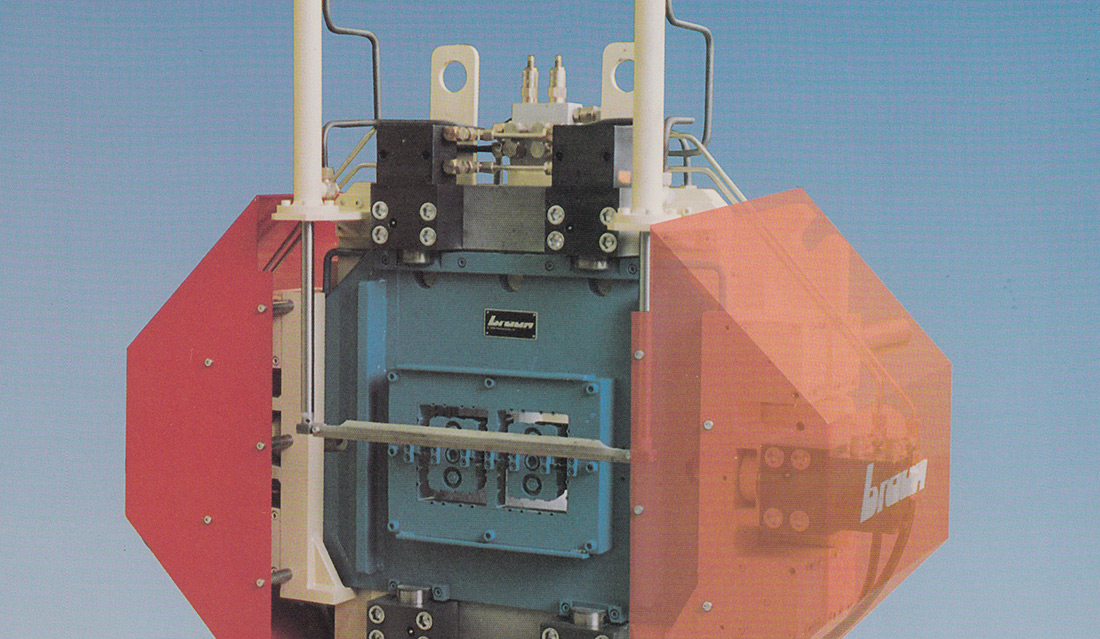

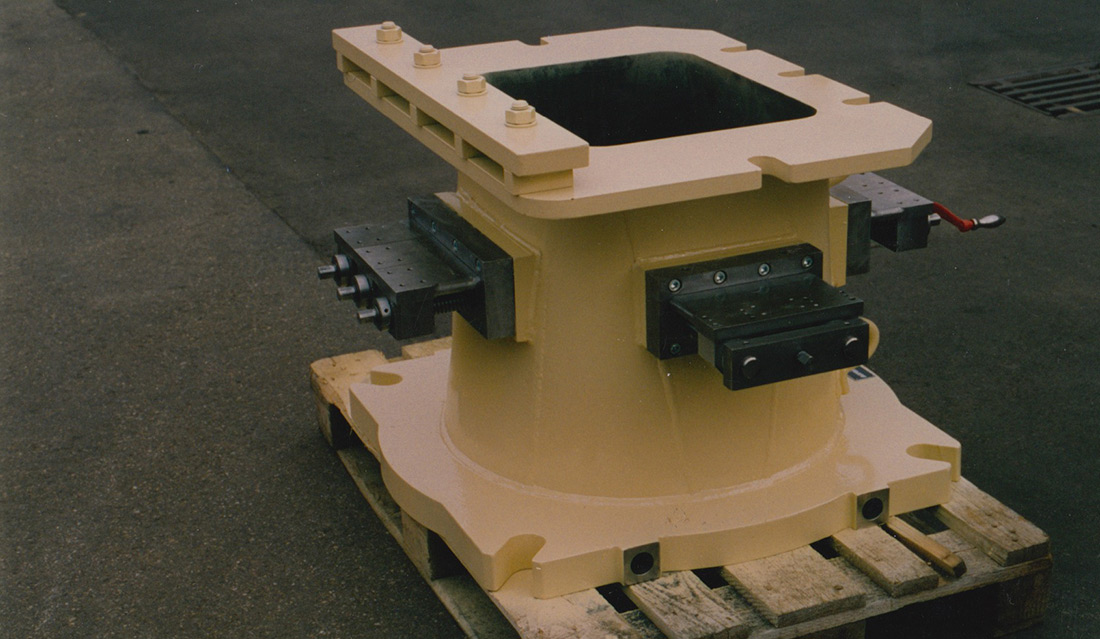

Construction of the first pressure head

Construction of the first assembly for the stiff extrusion unit

Introduction of VAUTID chilled iron castings in die engineering

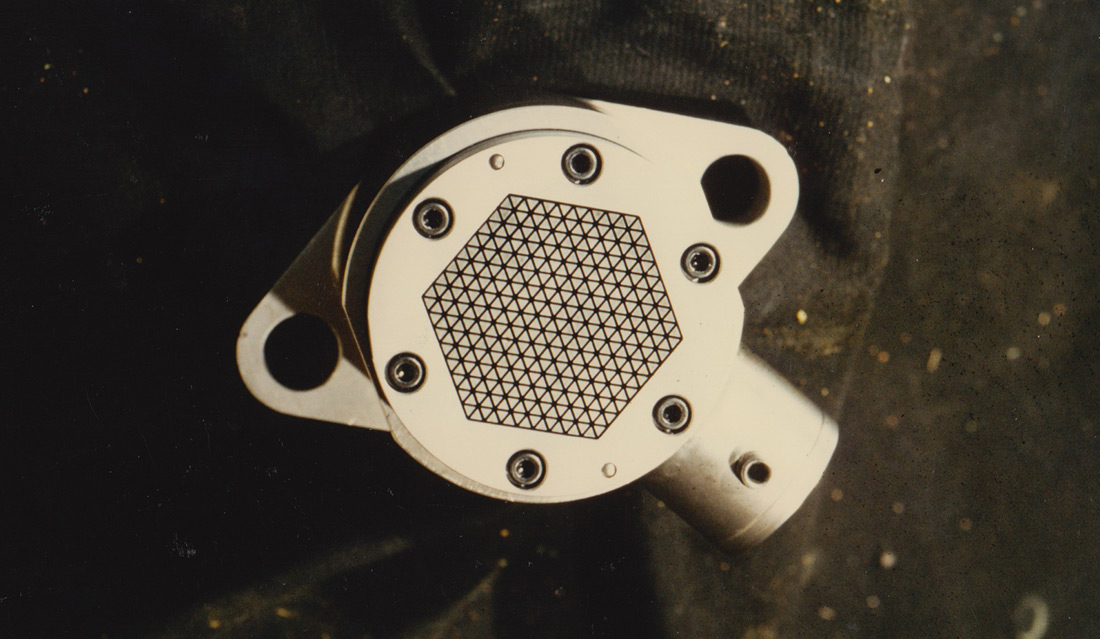

Construction of the first pressure heads and extrusion dies for technical ceramics

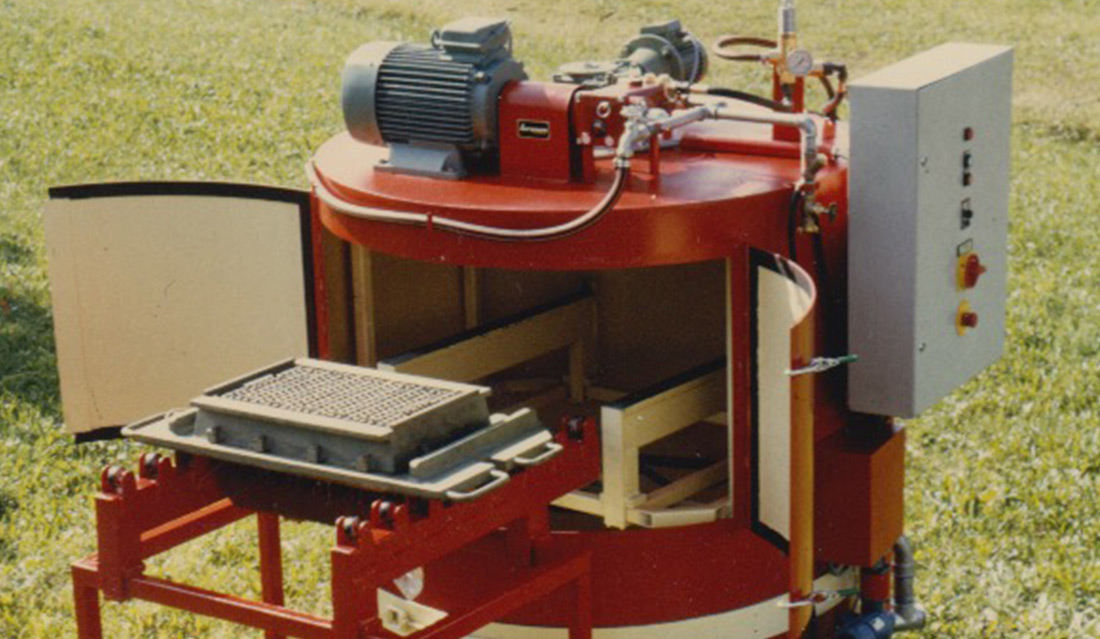

Development of the first special-purpose die cleaning machine

Construction of the first quick-change die loading system

Construction of the first pressure head with slide adjustment

Construction of the first die with threaded core bar assembly – B-TEC

Construction of the first die maintenance stand